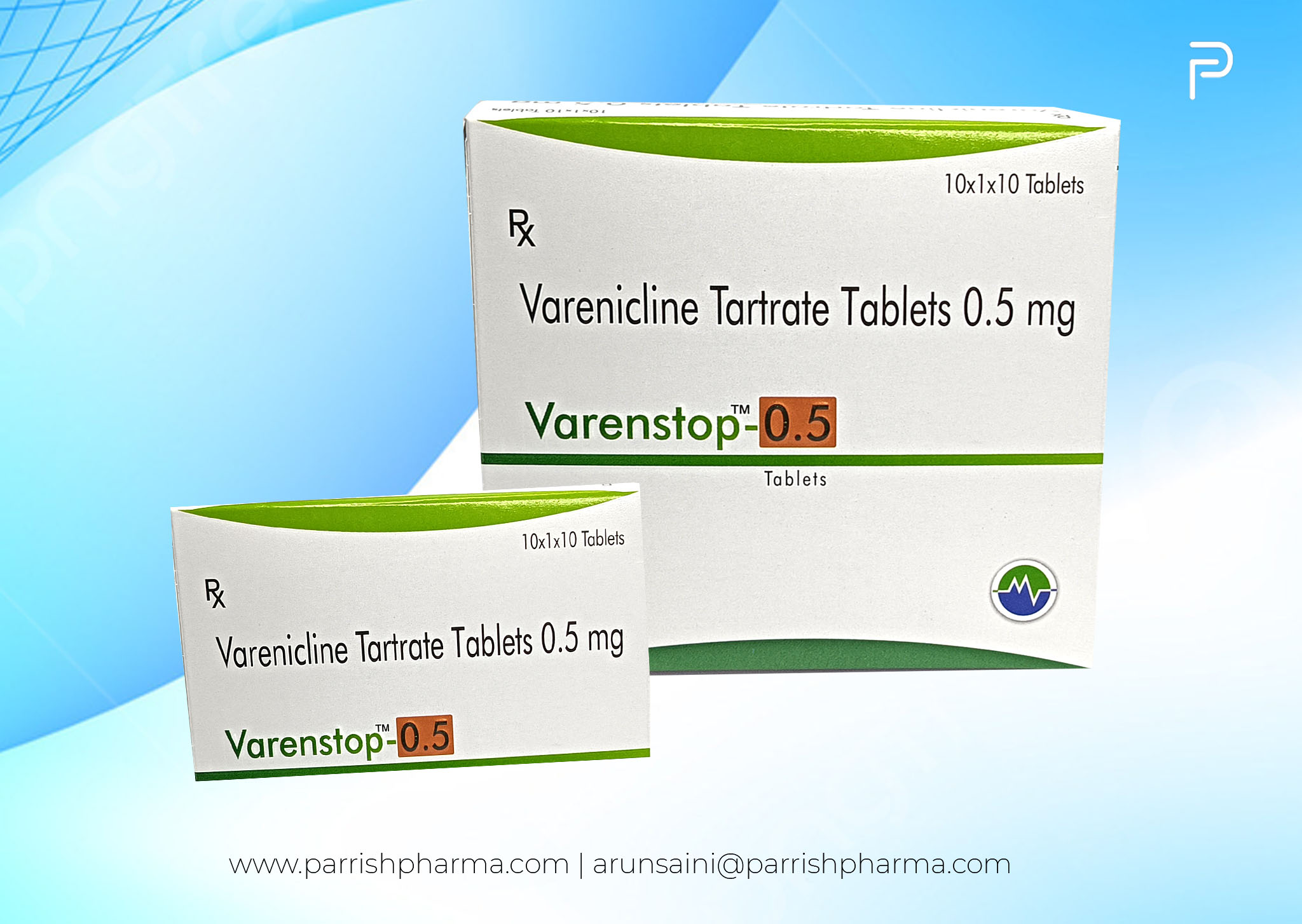

In the pharmaceutical industry, ensuring the quality standards for a product or service is of paramount importance. Quality assurance is driven by the objective of establishing and preserving customer trust in the product. Its primary aim is to identify defects at an early stage or to prevent them altogether. Quality assurance stands as the bedrock of regulatory adherence within the pharmaceutical sector. Manufacturing facilities are obliged to conform to a multitude of directives and standards laid out by various governing entities, such as the Food and Drug Administration (FDA) in the United States or the European Medicines Agency (EMA) in Europe. The task of quality assurance departments revolves around the establishment and maintenance of systems that guarantee compliance with these regulations. Through the implementation of comprehensive quality frameworks, pharmaceutical facilities can secure their operations in alignment with mandated standards, thereby mitigating the risk of regulatory violations and the accompanying penalties. Quality assurance departments bear the responsibility of ensuring diligent adherence to Good Manufacturing Practices (GMP) throughout the facility. The strict adherence to GMP enables pharmaceutical plants to minimize contamination risks, maintain consistent product quality, and enhance overall operational efficiency.